- Home >

- Research

In a robotic cell production system, which is appropriate for variable-mix, variable-volume production, robots need to grasp parts in various shapes accurately in desired poses (i.e., positions and orientations) for assembly tasks. To achieve this, parts are pre-aligned with parts feeders or jigs, and customized grippers for each part shape are used in the conventional approach. However, such customized equipment greatly heightens the cost of the production system, especially when the number of part shapes increases.

In this research, we develop a versatile robotic hand and a planning method of robust grasping strategy which can realize alignment and accurate grasping of parts. Our proposed robotic hand has multiple parallel stick fingers, and has enough degrees of freedom for achieving form closure grasps of parts in various shapes. The proposed robust grasping strategy is to align a target part by pushing it with the hand toward the form closure grasp configuration.

The combination of the hand and grasping strategy enables accurate grasping of parts in various shapes without visual sensors even when there are some uncertainty in their initial poses, and thus cost reduction of the production system is expected.

A demonstration video can be seen here.

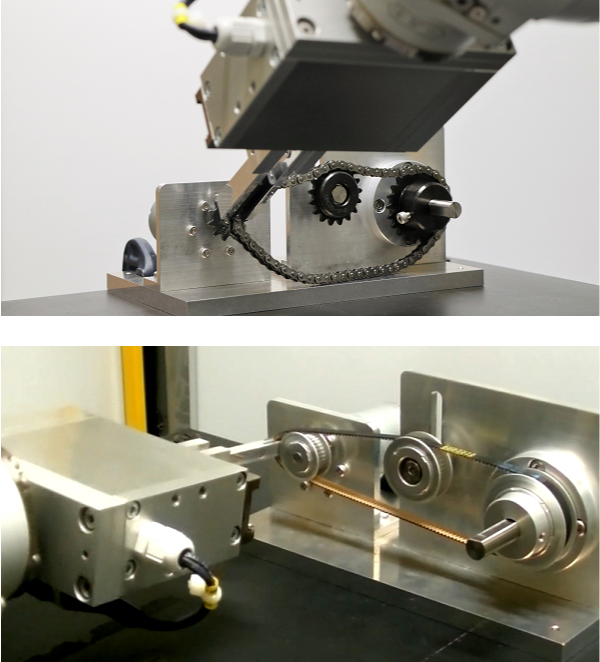

For realizing a versatile, flexible robotic assembly system, robots need to handle not only rigid parts but also flexible ones. In the robotic competition, "Assembly Challenge," held as part of the Industrial Robotics Category in the World Robot Summit 2018, roller chain or timing belt assembly were targeted as the most or the second most difficult tasks, which could not be achieved by any participating teams. Roller chains have both properties of flexibility and rigidity. Timing belts can be hardly stretched and there are individual differences. These characteristics make robotic assembly of those parts difficult.

In this research, strategies for assembling a roller chain to a set of sprockets or assembling a timing belt to a set of timing pulleys with a conventional parallel jaw gripper and with no external sensors are proposed. In the former case, we utilize the chain's property that the side bow may arise, etc. and develop a robust strategy against the uncertainty of the relative position of the chain to the gripper and the phases of the sprockets. In the latter case, we design the appropriate dimensions of the gripper jaws considering the belt's property and the slight clearance between the timing belt and the last pulley, and develop a strategy which can absorb individual differences of the belts.

The proposed strategies widen the availability of conventional parallel jaw grippers, and are expected to contribute to automation of flexible part assembly.

A demonstration video of roller chain assembly can be seen here, and that of timing belt assembly here.

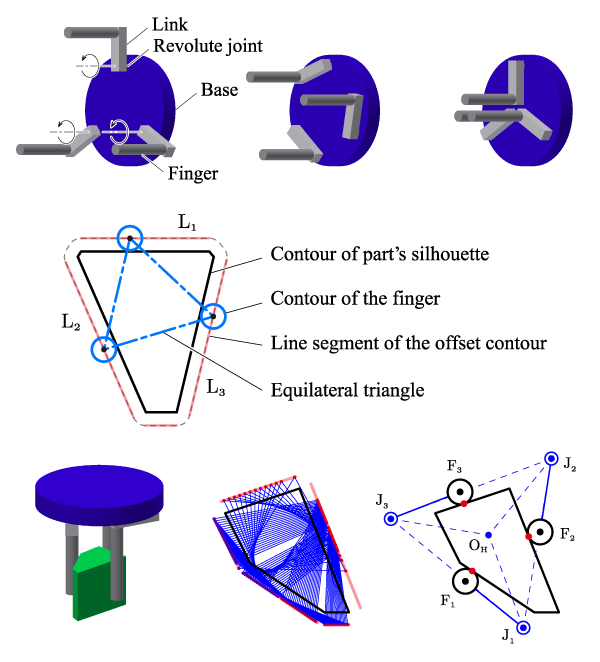

For handling parts in various shapes in a robotic assembly system, the development of a versatile robotic hand with minimally necessary mechanism is desired. A simple robotic hand with multiple stick fingers and a low degree of freedom (DoF) is one possible solution. In general, to design the mechanism of a hand, grasp planning of target parts is necessary. Unlike multi-DoF hands, feasible grasping configurations of such a low-DoF hand are greatly limited, and this must be considered in grasp planning.

In this research, we propose a method of grasp planning and designing of a low-DoF hand with parallel stick fingers, especially focusing on a 1-DoF chuck-type hand with a rotational link mechanism and three fingers. In our method, candidate grasping points on target parts are accurately obtained from a geometrical analysis considering the constraint of the hand mechanism. Then, a hand design optimization problem is solved to find optimal values of design parameters of the hand, minimizing the driving force of the actuator of the hand required for handling all the target parts in the assembly task.

A robotic hand which can handle variously shaped parts even with a low DoF can be designed by the proposed method, and it is expected to contribute to realizing a versatile robotic assembly system.

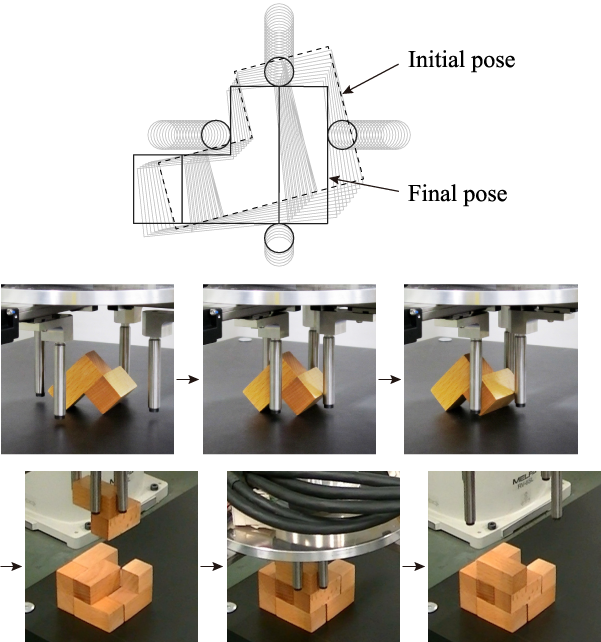

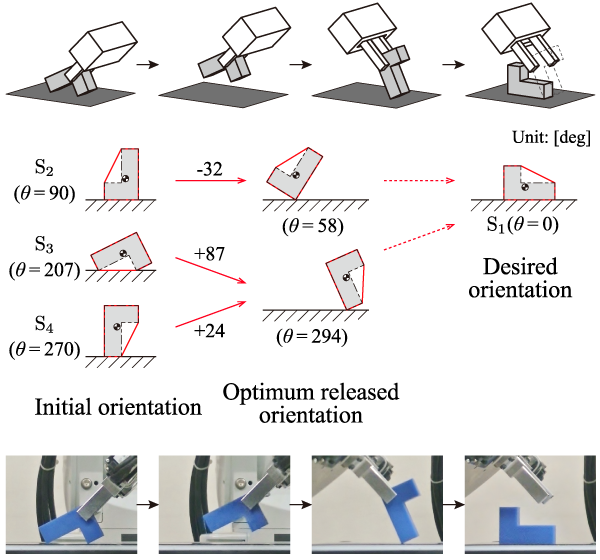

In a versatile robotic assembly system, robots need to reorient target parts from the initially supplied orientations to another ones appropriate for assembly tasks. The most common conventional strategy to reorient parts with a simple two-fingered gripper often requires more than a single pick and place motion for avoiding interference of the gripper with the workbench and keeping the robots away from the joint limits.

In this research, we propose a novel reorientation strategy for a parallel gripper, and develop a planning method of efficient reorientation sequence using the strategy. In our proposed strategy, a target part is allowed to be released in its unstable orientation and topple toward a desired final stable orientation while the part is released only in its stable orientation in the conventional strategy.

This strategy makes it easy to avoid interference of the gripper with the workbench and joint limits of the robot, and thus the efficiency of reorientation of a target part is expected to be improved.

In the conventional robotic assembly system, robots play back motion taught by human operators. In the teaching process, fine adjustment of robots with actual parts aligned in fixed poses with parts feeders or jigs is required for achieving accurate grasping and assembling, and it is time-consuming. Also, customized grippers for each part shape are used, which heightens the cost of the system for dealing with various part shapes. These are drawbacks for realizing variable-mix, variable-volume production.

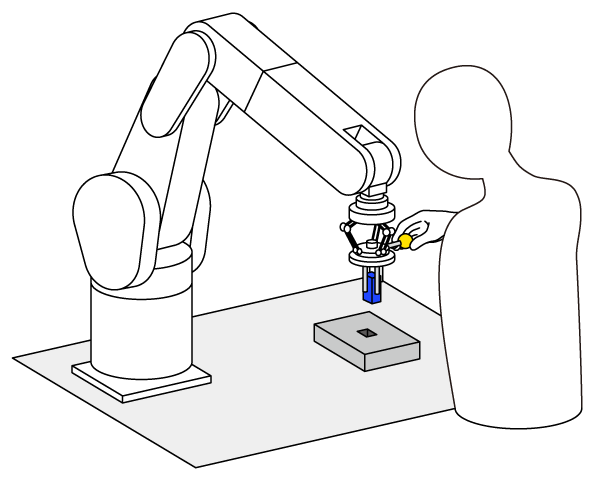

In this research, we aim to develop a macro-micro robotic system such that human's implicit knowledge/skill on assembly tasks can be transferred to the robot through direct teaching, and also parts in various shapes can be manipulated with a versatile robotic hand mentioned above.

The proposed robotic system is expected to achieve assembly tasks of parts in various shapes, reducing the teaching process and eliminating customized equipments.

* This is a collaborative research with Kobe University.

Stroke patients may have paralysis in some body parts. However, their motor function is expected to recover by early stage rehabilitation. One efficient method of stroke rehabilitation is that therapists move paralyzed body parts of the patients at the moment they try to move the parts voluntarily.

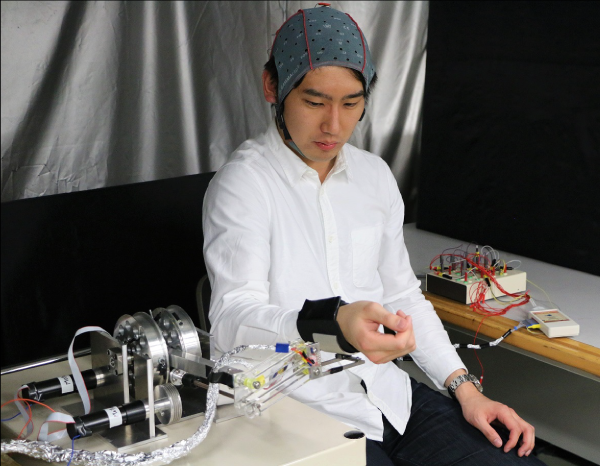

In this research, we aim to develop a robotic system which can achieve such an efficient stroke rehabilitation for a paralyzed upper limb instead of a human therapist. Toward this goal, we propose (i) a brain-computer interface (BCI) method to detect the motion intention to try to move his/her upper limb, using their electroencephalogram (EEG), and (ii) a redundant drive method to realize proper compliant motion of the robot supporting the upper limb.

The integration of these two methods enables the robot to assist motion of the upper limb of the patient softly at the appropriate timing, and thus efficient rehabilitation is expected to be achieved.

* This is a collaborative research with Ritsumeikan University, University of Reading (UK), and University College London (UK).